Process Documentation

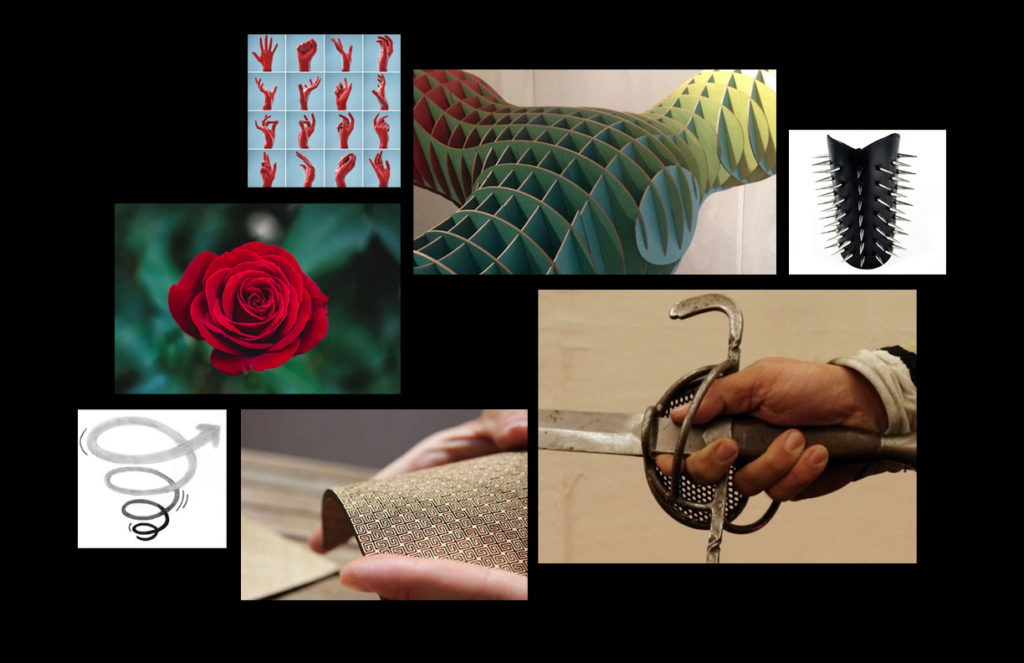

When presented with the prompt for this project, to make a cup holder item, I constructed a moodboard of images and themes that I wanted my object to reflect.

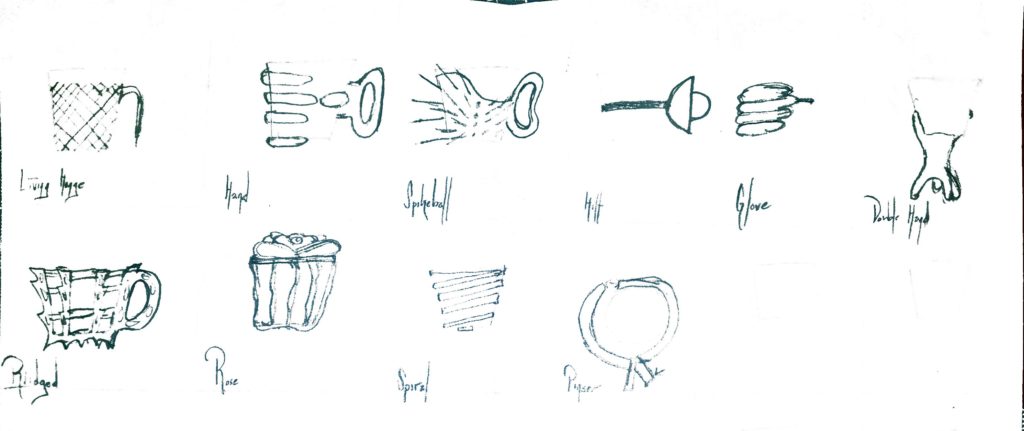

I first decided I wanted to have some kind of novelty holder that served aesthetic functions, as I have no issues with cup use that I saw I needed a fix for. I drew thumbnail sketches to generate a variety of different design ideas.

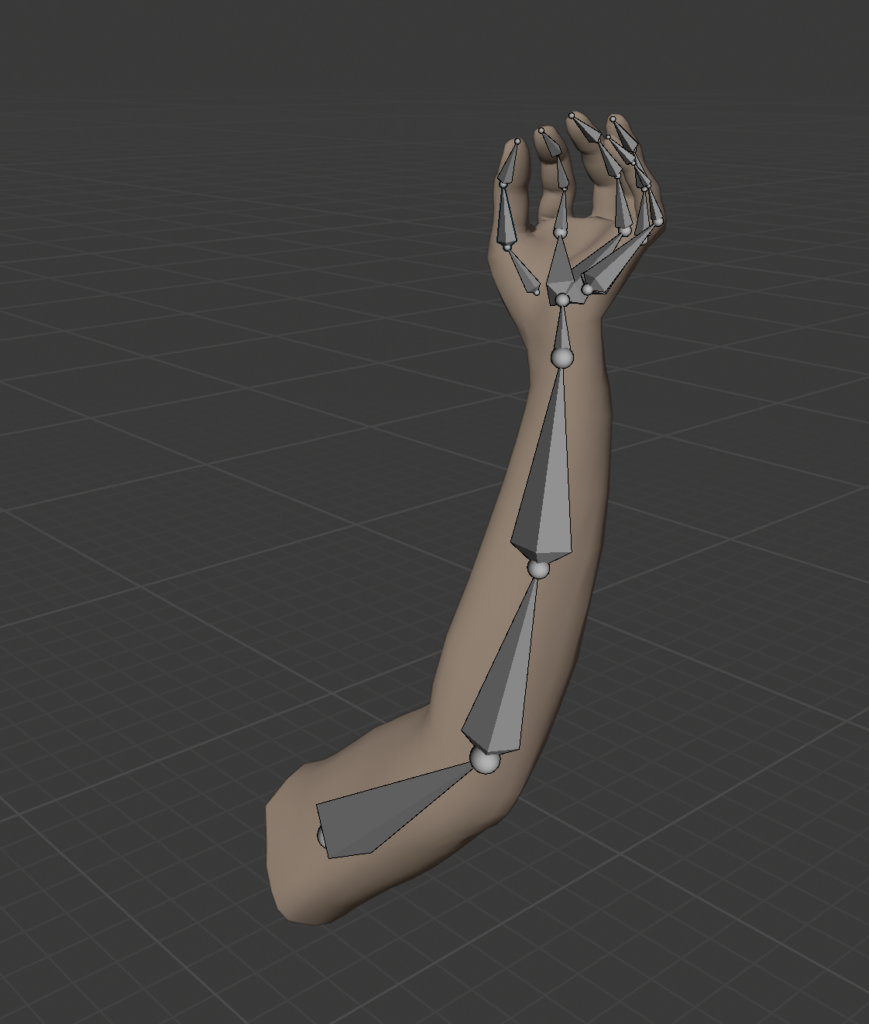

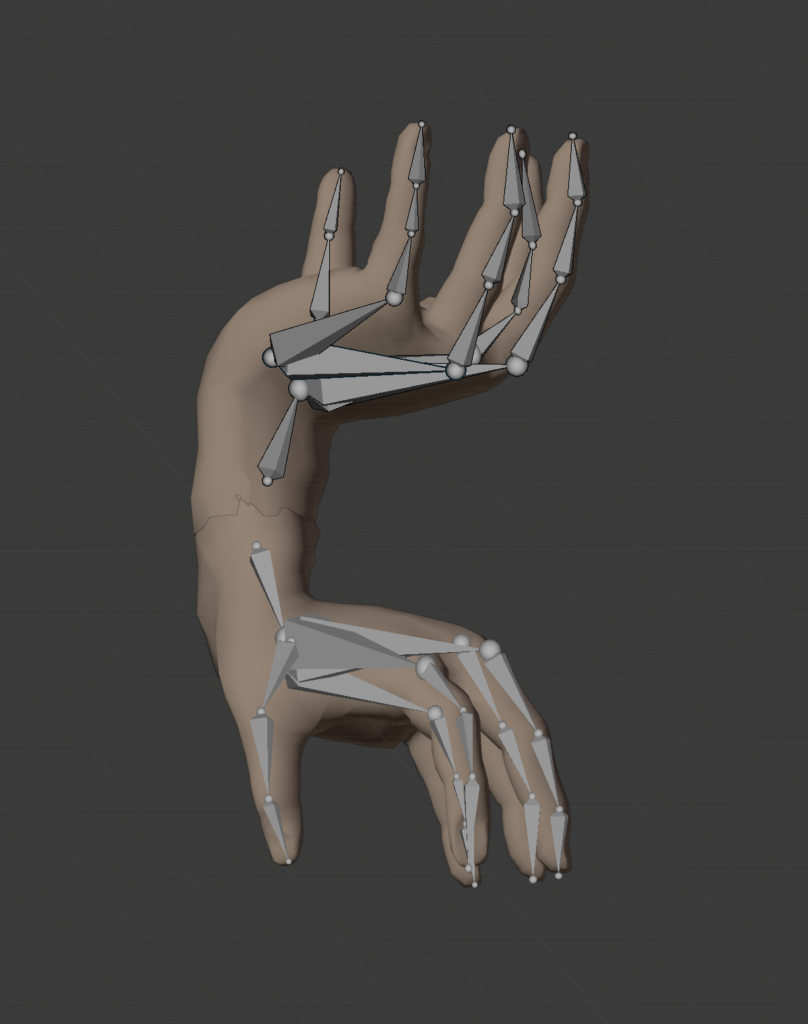

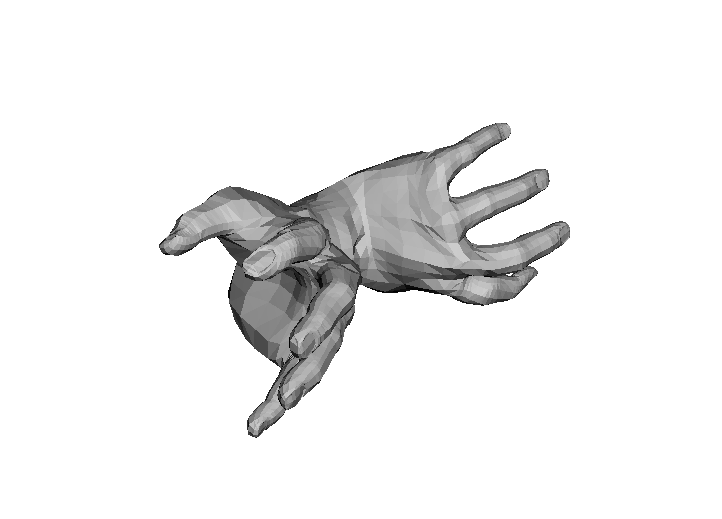

After decided to go with the double-handed design, I began studying my own hand and physiological features in order to determine what exact shape my hand makes when I grasp a cup from beneath. I then obtained a manipulable hand file and loaded it into blender in order to set the positioning of each joint and bone in the hand so the position would both hold the cup and stand flat on the table, as well as set the correct sizing, and center of mass so the hands would not fall over when holding up an item. After finishing the model, I exported it as an STL mesh file.

Completed STL file

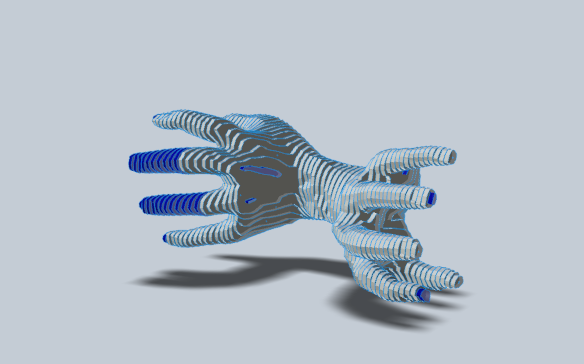

I uploaded that slice file into Slicer for Fusion360 and tried to determine the most efficient way to slice the file that would still maintain the integrity of the form. I initially decided on a cross-sectional form that would slot together. Upon construction, I discovered the internal stresses of the model were high, and as a result of that and very thin members, the piece was fragile and broke easily.

Cross-Sectional Model

DXF for Cross-Sectional Model

Remains of broken Cross-Sectional Model

After discovering the fragility of the corss-sectional model, I switched to a layered model approach and laser cut the piece out again.

Layered Slice

DXF Slice File Output

I then constructed the hands layer by layer, utilizing a strong adhesive to ensure stability and exact placement of each of the pieces.

Nearly Complete Piece